Plant Operations

Operating License

In 2015, the Operating License Application (OLA) was submitted to FANR by ENEC on behalf of ENEC Operations and includes details about the design, operation and eventual decommissioning of the first two Units at Barakah. A separate OLA was submitted by ENEC Operations to FANR in 2017 for Barakah Units 3 and 4.

In February 2020, the Federal Authority for Nuclear Regulation (FANR) issued an Operating License to ENEC Operations, ENEC’s subsidiary mandated to operate and maintain the four Units at Barakah, allowing them to start safely loading fuel into Barakah Unit 1.

In March 2021, FANR issued the Operating License for Unit 2 of the Barakah Nuclear Energy Plant to ENEC Operations. In June 2022, FANR issued the Operating License for Unit 3 of the Barakah Plant to ENEC Operations. In November 2023, FANR issued the Operating License for Unit 4 of the Barakah Plant to ENEC Operations.

All of the Operating Licenses issued authorize ENEC Operations to commission and operate each of the four units of the Barakah Plant for 60 years.

The Operating Licenses were issued following a rigorous series of inspections and extensive study of the Operating License Application (OLA) documents by FANR. Since 2009, ENEC and ENEC Operations have been subject to more than 500 inspections by FANR. Additionally, more than 100 independent inspections, reviews and assessments by the World Association of Nuclear Operators (WANO) and the International Atomic Energy Agency (IAEA) have taken place. All of the reviews and checks have ensured the highest international standards are met throughout the development and delivery of the UAE Peaceful Nuclear Energy Program.

Loading Fuel

Following receipt of each Operating License, ENEC Operations transferred the first nuclear fuel assemblies into each reactor building. This is carried out by using a special fuel transfer system that takes the fuel from storage to the reactor building where it is then lowered by large cranes into specific locations inside the reactor pressure vessel. At this time, the fuel has not been irradiated and can be handled without protective equipment.

The work is closely monitored at all times and is carried out in line with robust procedures and international best practices.

In March 2020, ENEC Operations completed fuel load in Unit 1 , and then completed the same process for Unit 2 in March 2021, Unit 3 in June 2022, and finally Unit 4 in December 2023.

Independent Inspection and Verification

After all of the initial fuel assemblies have been loaded into the reactors, a team of experts from the International Atomic Energy Agency (IAEA) visited the Barakah Plant to perform a Physical Inventory Verification inspection. The purpose of this inspection was to identify all fuel assemblies loaded into the reactor core using their unique serial numbers, verifying that all nuclear material declared and stored at Barakah is accounted for. In this way, the IAEA confirmed that none of the material has been diverted away from peaceful use.

The first inspection was completed in March 2020. The successful conclusion of the inspection demonstrated that the UAE remains committed to non-proliferation and transparency.

Following the inspection, a number of tests were carried out and the top of the Reactor Vessels were re-fitted and sealed. Over the following weeks a series of tests were carried out that are designed to check that every component system on the reactor operates as it should.

Reactor Startup

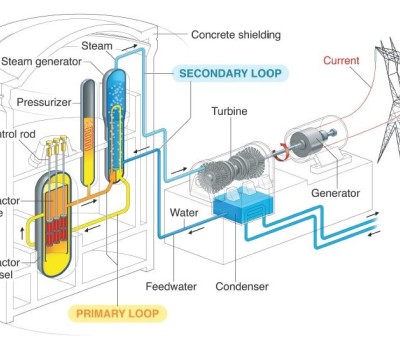

After these tests have been completed and verified, ENEC Operations’ staff began the process of starting the reactor and achieving a sustained nuclear chain reaction inside the reactors. Reactor startup, also known as First Criticality, is the first time the operators release a neutron, which collides into a Uranium atom (the Uranium pellets are loaded inside the fuel assemblies which are inside the reactor), which releases heat and more neutrons. The new neutrons then hit more Uranium atoms, which split, releasing more heat and neutrons and so on. This is called fission, and it continues by itself, controlled by the operators using special equipment.

We then allow the reaction to continue, step-by-step, increasing the amount of heat inside the reactor. We slowly increase the rate of fission and the amount of heat produced inside the reactor until we can make enough steam to turn the turbine, which spins the generator and makes clean electricity.

Grid Connection

In a nuclear energy plant, grid connection happens in the same way as in any gas, coal or oil-fired plant. The equipment and process for grid connection are all the same. The main difference with any fossil-fueled plant is that a nuclear plant uses uranium pellets as fuel to generate heat, which creates steam that spins a turbine, which in turn drives the electric generator to produce electricity. This process creates zero carbon emissions.

To connect a nuclear plant to the electricity grid, the reactor operators slowly increase the heat generated by the reactor to generate enough steam to begin spinning the turbine and driving the generator. Once the reactor is at about 15% power, enough steam is created to have the turbine spinning at its optimal speed of 1,500 revolutions per minute (RPM). This allows the electric generator to prepare to synchronize and connect to the national electricity grid.

Power Ascension Testing

With the plant connected to the electricity grid, ENEC Operations’ operators run a series of tests as part of the Power Ascension Testing (PAT) process. They increase the reactor power in stages, testing and monitoring plant’s components and ensuring that electricity is being generated safely. After several months, the Unit is brought to 100% power and allowed to operate at maximum output capacity.

Throughout this process, numerous tests are conducted on the systems as part of an intensive program lasting several months.

After completion of all testing, the reactors are shut down for a maintenance check, known as an outage, before starting full commercial operation. This process is only completed prior to first commercial operations period for each reactor and is now complete across the Barakah fleet of reactors.

Commercial Operations

With the reactors operational again, ENEC Operations’ operators, engineers and technicians determine that each unit of the Barakah Plant met all requirements in accordance with national regulations and the highest international safety standards. They operated the plant at 100% power for a pre-determined period of time, at the end of which each Unit was declared commercially operational, delivering clean electricity to the UAE electricity grid 24/7.

Commercial Operations marks the end of testing for a nuclear reactor, declaring it fully operational and meeting all national requirements and international standards.

Today, the Units are generating vast amounts of clean and reliable electricity, 24 hours a day, seven days a week, for the next 60 years, only stopping to refuel for a brief period every 12 to 18 months.